Get expert concrete flooring in Markham that's crafted for performance and compliance. You'll get precision-engineered mixtures, verified slump/air/temperature and dampness/alkalinity/moisture level assessment for predictable curing and bond. We specialize in surface preparation/diamond polishing to ICRI CSP, fissure/seam restoration, and rapid-dry primers. Opt for honed concrete surfaces, resin-based/advanced coating solutions, or pigmented/enhanced appearances with UV-stable sealers and certified floor measurements and layer dimensions. Our team confirms certifications, guarantees, and schedules to control risk, cost, and downtime-subsequently, discover how customized choices suit your space.

Core Findings

- High-quality concrete flooring installations in Markham: featuring engineered mix designs, steel reinforcement, expansion joints, and proper curing following building standards for consistent strength and longevity.

- Licensed professionals carrying WSIB and liability insurance, providing comprehensive written specifications, quality assurance testing, warranties conforming to ASTM/CSA specifications, and dependable completion schedules.

- Surface preparation and moisture management: RH and pH analysis, CSP profiling, repair of cracks and joints, moisture barriers, and compatible primers for installations that meet warranty requirements.

- Regarding polished, stained, or dyed floor treatments, we provide professional services encompassing advanced grinding methods, lithium-based concrete strengthening, UV-stable protective coatings, non-slip treatment options, and test applications to ensure aesthetic satisfaction.

- Our epoxy/polyaspartic systems feature precise mil thickness, vapor-blocking primers, non-slip aggregates, and certified FF/FL measurements for creating durable, low-maintenance floor solutions.

Understanding Professional Concrete Flooring Services in Markham

Despite concrete's apparent simplicity, expert implementation in Markham directly impacts load-bearing capabilities, surface uniformity, water control, and long-term expenses. You need a professional installer who carefully adjusts mixture formulation to accommodate concrete depth, reinforcement specifications, and ground conditions, then validates slump characteristics, air entrainment, and temperature parameters for predictable curing. Industry experts plan for regional climate conditions-such as freezing and thawing, snow-removal chemicals, and atmospheric moisture-by incorporating controlled air content, appropriate water-cement levels, and correct joint spacing.

You also eliminate compliance risks. Skilled crews understand building codes, oversee vapor barriers, reinforcements, and curing compounds, and record compaction and compressive strength tests. Expert finishing delivers FF/FL targets, reducing trip hazards and racking issues. Appropriate drainage angles and isolation joints stop heaving and cracking. Simply put, professional methods protect structural reliability, reduce callbacks, and extend service life.

Polished Concrete: Creating Elegant Spaces with Enduring Quality

Enhance functionality and appearance with polished concrete that delivers durable, clean, gleaming floors crafted for heavy use and longevity. You get a hardwearing surface perfected through progressive metal-bond grinding, resin honing, and lithium densification to optimize wear resistance and reduce porosity. We then finish and seal to secure durability and resistance.

Achieve the gloss you require-from low-gloss to high-shine results-while ensuring slip resistance through strategic aggregate selection and precise light reflectivity management. This increases lighting performance, reduces maintenance, and streamlines cleaning procedures. Surface flaws and seams are resolved before finishing to prevent telegraphing and premature wear.

Expect consistent lifecycle expenditures, quick return-to-service, and straightforward compliance with cleanliness and particulate regulations. Concrete polishing provides reliable performance without surface treatments, peel, or adhesion failure concerns.

Epoxy Coatings for Garages, Shops, and High-Traffic Areas

You need epoxy coatings that can resist wear and tear, tire marks, chemicals, salt exposure, and various solvents without softening or staining. To ensure this type of performance, you should mandate mechanical substrate preparation (through grinding or shot blasting), moisture and pH testing, and a suitable primer to secure optimal adhesion. Then you'll need to apply the epoxy following manufacturer MVT guidelines, control film thickness and cure times, and top it off with a UV-stable topcoat where traffic or sunlight exposure requires it.

Material Durability and Chemical Properties

When operations require a floor that will perform under stress, epoxy coatings offer high compressive strength, abrasion resistance, and proven chemical protection for garages, fabrication shops, and high-traffic corridors. You achieve longevity from strong molecular bonds within the crosslinked matrix, translating to impact protection, structural integrity, and extended service life. Epoxy resists vehicle traffic, heavy equipment, and wheeled loads without surface damage or deterioration.

Furthermore, you minimize degradation from numerous harmful substances like oils, coolants, and road treatments. The durable film prevents penetration, limiting deterioration and material breakdown when exposure occurs. Heat cycles and moisture are controlled with limited expansion, maintaining bond integrity. Specify solids content and resin-hardener ratios to suit environmental demands. With the proper solution, you reduce maintenance, lengthen maintenance periods, and ensure uninterrupted workflow.

Surface Preparation and Application

Prior to epoxy application, thorough surface preparation establishes performance limits. You must verify slab moisture, pH, and tensile pull-off, then clear away surface contaminants and weak cement paste. Carry out micro surface profiling by means of shot blasting or diamond grinding to reach the required concrete surface profile, ensuring clean, open pores. Address surface defects with joint filling compounds, and carefully prepare edges where problems typically begin.

Start by controlling porosity with rapid-dry primers that accommodate residual moisture and accelerate recoat times. Broadcast to rejection in areas anti-slip characteristics or additional thickness is required, then distribute the body coat with roller or squeegee application at the target thickness, keeping wet edge flow and complete coverage. Regulate ambient and substrate temperatures, dew point, and airflow. Finish with a UV-resistant topcoat to protect against surface damage, chemicals, and provide straightforward maintenance in garages and busy spaces.

Decorative Concrete Staining and Dyeing Solutions for Custom Patterns

We can create an exact color palette by applying acid stains for variegated tones or water‑based dyes for crisp, uniform hues that align with your branding. We'll engineer decorative surface patterns-saw‑cuts, stencils, layered applications, and controlled mottling-to create stone, tile, or graphic looks with uniform results. To secure color and performance, we'll choose the optimal sealer (polyaspartic, penetrating, or polyurethane), then create a care program with pH‑neutral cleaning and scheduled sealer applications according to wear.

Color Scheme Choices

Color drives performance in concrete design, and staining and dyeing techniques deliver accurate, reproducible effects. You choose from standardized color palettes that match brand specifications or design schemes, then we confirm with on-site samples under your actual lighting. Acid stains produce variegated Earthy tones-sand, umber, slate-ideal for commercial, public, and retail environments requiring subtle warmth. Solvent and water-based dyes broaden into vibrant precious stone hues-peridot, tanzanite, rhodolite-supporting bold wayfinding and premium merchandising.

We analyze surface conditions like porosity, moisture content, and cement makeup to predict uptake, then define preparation ratios, processing time, and application steps for consistency. Ultraviolet-protective coatings preserve coloration, while gloss levels tune reflectance targets. You achieve consistent coloring across processes with recorded mixing specifications and batch controls, ensuring consistent, maintainable results.

Effects of Pattern and Texture

After establishing hues established, patterns and textures function as functional components that control traffic, minimize glare, and define areas. You can specify dyed or tinted concrete as the foundation, then layer strategic patterns to achieve targeted benefits. Scored grids, saw-cut borders, and laser etched patterns establish wayfinding solutions and merchandise areas without extra hardware. Impressed finishes deliver non-slip surface texture while simulating get more info natural materials or branded designs. Reactive stains create variegation; liquid stains achieve consistent, reproducible tones for precise patterns.

We carefully map circulation paths, dock approaches, and retail vignettes where surface patterns indicate motion and stopping zones. Matte finishes reduce glare with LED illumination, eliminating glare on camera and improving visual comfort. Edge detailing and inlays complement identity requirements, maintaining resilience, protection, and rapid setup.

Sealing and Maintenance Tips

Achieve optimal long-term performance by aligning the sealer to the coloring method, exposure conditions, and traffic demands. Choose penetrating sealers for permeable, UV-protected stained floors; choose high-solids polyurethanes or polyaspartics where abrasion and chemical exposure are common. Validate VOC restrictions and slip prevention values. Prep carefully: ensure neutral pH following staining, complete 200-400 grit burnishing if specified, and install within the manufacturer's specified recoat window.

Establish periodic evaluations to monitor surface shine, film integrity, and surface damage. Track wear patterns at critical facility points and transit paths; arrange targeted recoat ahead of surface degradation. Put in place a consistent spill cleanup procedure: isolate, blot, neutralize, and rinse - avoid acidic cleaners or undiluted degreasers. Utilize microfiber dust control, autoscrub with pH-neutral detergent, and apply sacrificial finish in heavy-use sections. Track maintenance data to improve lifecycle costs.

Essential Guidelines for Surface Preparation and Moisture Control

Before installing any coating or overlay, rigorous surface preparation and moisture control establish warranty eligibility and performance. Initial steps include performance testing: ASTM F2170 RH probe analysis, ASTM F1869 calcium chloride testing, and pH measurements. Next, eliminate contaminants, then execute substrate profiling to the required ICRI CSP, using mechanical preparation through shot blasting or diamond grinding. Repair all cracks, spalls, and joints with suitable compounds, and vacuum thoroughly to achieve a dust-free surface before the priming phase.

Handle moisture issues at the source. Check vapor barriers beneath the slab exist and function; where barriers are absent or compromised, implement surface moisture control solutions suitable for your slab's moisture levels. Manage structural cracks and seams using flexible sealants to accommodate shifts. Pick epoxy or urethane primers that work with current moisture conditions. Track all readings, surface prep, and cure times to meet warranty specifications and ensure predictable performance.

Commercial, Industrial, and Residential Services

Proper preparation and moisture management create the groundwork for performance across segments, but application priorities vary by specific needs. In commercial environments, you must coordinate wear patterns, design elements, and lifecycle costs. You select eco-friendly materials for LEED compliance, hardening agents for abrasion resistance, and surface treatments optimized for anti-slip properties without compromising ease of cleaning. You must account for temperature-related movement at entrance areas and sun-exposed atriums.

For industrial environments, it's essential to consider protection against impacts, chemical exposure, and forklift operations. You carefully plan joint patterns for storage areas, calculate proper reinforcement, and implement coatings that handle thermal expansion from process heat. Acoustic control is important in proximity to testing labs and QC departments.

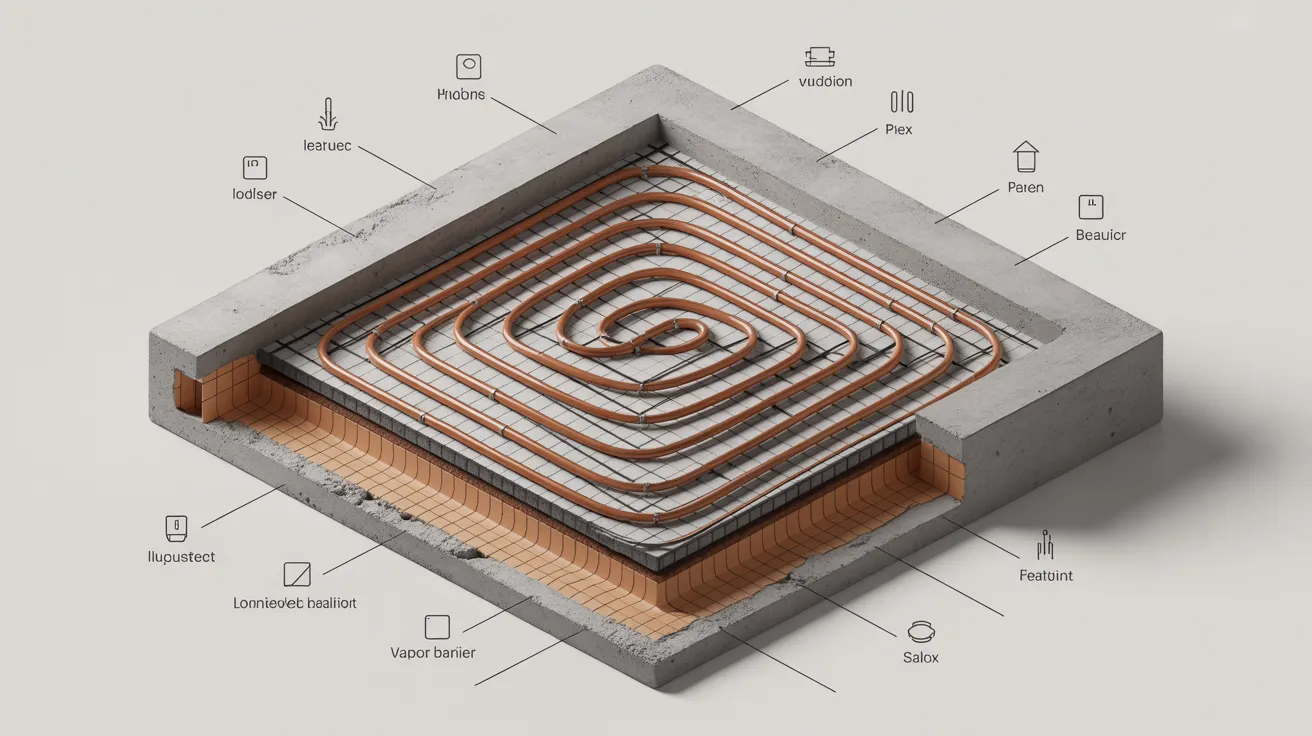

For homes and living spaces, we prioritize comfort and easy maintenance. We incorporate acoustic dampening materials, radiant-prepared base layers, and high-performance sealers that ensure safe footing while keeping a cozy aesthetic.

Choosing the Right Contractor: Qualifications, Guarantees, and Scheduling

When sourcing a concrete floor installer in Markham, assess qualifications and work ethic with the same attention to detail you expect from mix designs. Verify the firm employs licensed installers, has WSIB and liability insurance, and maintains manufacturer certifications for the required system (polished, epoxy, urethane-cement, or overlays). Review project references with comparable loads, exposure, and schedule requirements.

Insist on a detailed scope outlining: base preparation, moisture mitigation, reinforcing elements, placement, final touches, and performance testing. Ensure a warranty that specifies coverage, restrictions, and service times; tie it to performance standards specifically compressive strength, floor profile (FF/FL), and film thickness.

Review timeline viability by verifying: manpower allocation, tool availability, curing intervals, and fallback provisions for climate impacts and material shortages. Establish a documented conflict resolution process, escalation contact list, and daily reporting structure.

Financial, Maintenance, and Value Assessment

With the scope, warranty, and schedule, match financial planning with long-term operational efficiency, rather than the base price. Evaluate installation expenses combined with lifecycle pricing to incorporate structural requirements, reinforcement details, joint planning, curing procedures, and protective coatings. Specify surface treatments appropriate for wear tolerance, chemical exposure requirements, and slip resistance factors to prevent early-stage issues.

Define service intervals before starting the pour. Schedule cleaning chemistry, resealing schedules, and crack mitigation techniques to maintain surface appearance and dimensional standards. Account for budget for surface refinishing work, expansion joint updates, and moisture control measures where applicable.

Evaluate total cost of ownership: energy reflectance (reduced lighting expenses), service intervals for maintenance, and projected service life. Document warranty terms related to operational and environmental requirements. Measure resale value by demonstrating compliant surfaces, low pending maintenance, and assignable warranties. You'll minimize unforeseen spending and preserve asset value.

FAQ

Do You Accommodate Off-Hours Implementation to Minimize Impact on Operations?

Indeed. We offer after-hours and weekend installation scheduling to limit downtime. We arrange overnight scheduling and deploy emergency crews when needed, while staging activities to ensure access and safety. Our crew oversees curing procedures, noise reduction, and dust management to meet operational constraints. We deliver thorough planning, customized site arrangement, and quick deployment. You'll get progress updates, quality control confirmation, and a documented handoff, ensuring your facility reopens on time with durable, compliant, and clean results.

Is It Possible to Install Underfloor Heating With Concrete Flooring Solutions?

Indeed, you can integrate radiant floor heating with concrete flooring systems. Think of it as forging Excalibur: accuracy is crucial. You choose hydronic systems for spacious areas and optimal energy use, or electric mats for targeted zones and rapid response. You align slab thickness, insulation, vapor barriers, and control joints to safeguard tubing/cables. You validate load calculations, spacing, and manifold/electrical layouts, then commission pressure and continuity tests, guaranteeing uniform heat, minimal thermal lag, and durable performance.

Which Eco-Friendly and Low-VOC Materials Do You Offer?

You can select eco-friendly options incorporating low-volatile sealers, water-based epoxies, and high-solid polyurethanes to lower environmental impact and installation time. Choose formulations with reused aggregates, SCMs (fly ash, metallurgical slag), and regional aggregates to reduce embodied carbon. Opt for lithium-silicate densifiers with minimal emission characteristics. Request polished concrete to remove surface treatments where feasible. You'll obtain long-lasting, damage-resistant surfaces, meeting LEED/WELL requirements, without impacting curing duration, adhesion, or lifecycle performance.

Do You Handle Permitting or Liaise With Condominium Boards in Markham?

We offer permit assistance and condo coordination in Markham. You won't have to deal with red tape; we handle applications, file drawings, and track approvals. We coordinate with property managers, security, and boards to align bylaws, noise windows, elevator bookings, and load limits. We deliver insurance certificates, WSIB, site-specific safety plans, and engineer letters as required. We provide you with clear timelines, stakeholder updates, and documented compliance, making sure your project stays on schedule and ready for inspection.

How Well Can You Match Current Concrete Finishes in Partial Renovation Projects?

Indeed, you can match existing concrete finishes while undertaking partial renovations. Commence with a thorough assessment, performing mix design analysis, aggregate analysis, and finish calibration. Apply color matching using pigments, stains, or dyes calibrated with test panels. Carry out texture replication using custom trowel patterns, shot-blasting patterns, or textural impressions. Regulate cure rates and gloss with surface densifiers and sealers. Verify with side-by-side mockups under project lighting to ensure seamless integration.

Closing Remarks

You're looking for a floor that works like a precision machine-built to spec, clean, and long-lasting. With concrete polishing, epoxy coatings, and stain treatments, you'll match design with functionality, foot traffic, and lifespan. Proper prep and moisture control eliminate expensive repairs. Review qualifications, guarantees, and timelines to ensure high value and low liability. When you select proven Markham specialists, you'll secure a finish that stands up to heavy use, harsh substances, and operational delays while reducing upkeep needs and lifetime expenses for years.